Bread Recipe Autonomous Device (BRAD)

Automated bread maker

The Bread Recipe Autonomous Device (BRAD), is my undergraduate senior design project aimed at simplifying the bread making process by automating the dispensing, mixing, kneading, and baking stages. Our team’s motivation behind this project was to provide a more convenient and accessible way for consumers to make and enjoy fresh, healthy bread at home.

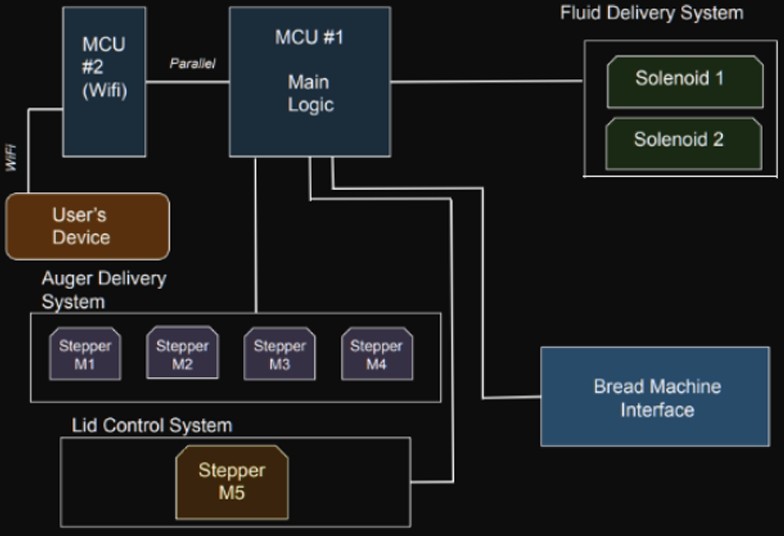

BRAD is composed of various subsystems, such as the solid dispensing subsystem, the liquid dispensing subsystem, the bread machine interface, lid opening and closing mechanism, and the logic circuitry. The key features of BRAD include a remote connection to the device through a virtual private network that can be accessible through the internet, a bread pan with a durable non-stick coating for easy cleaning, and the ability to add new recipes and ingredients using simple, 3D printed containers. The actual bread machine itself is a standard off the shelf bread maker, this project simply automates the process of using it.

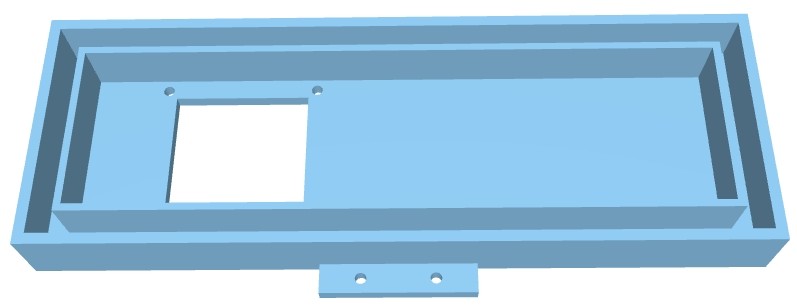

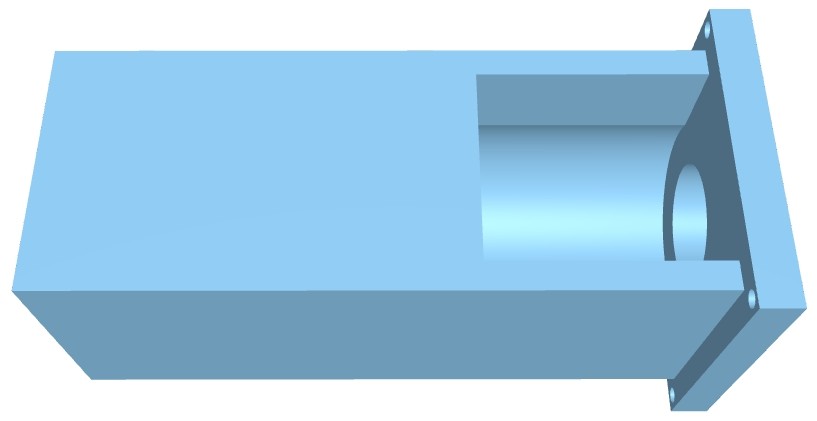

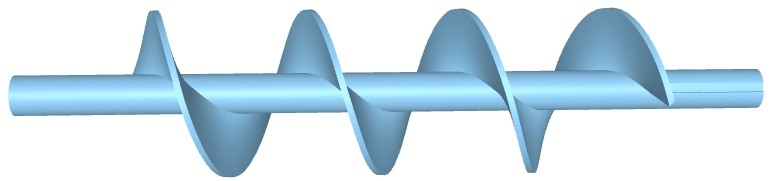

The base of the ingredient container feeds into the auger housing where a Nema 17 stepper motor spins the auger bit which pushes out the ingredient and pours it into the bread maker.

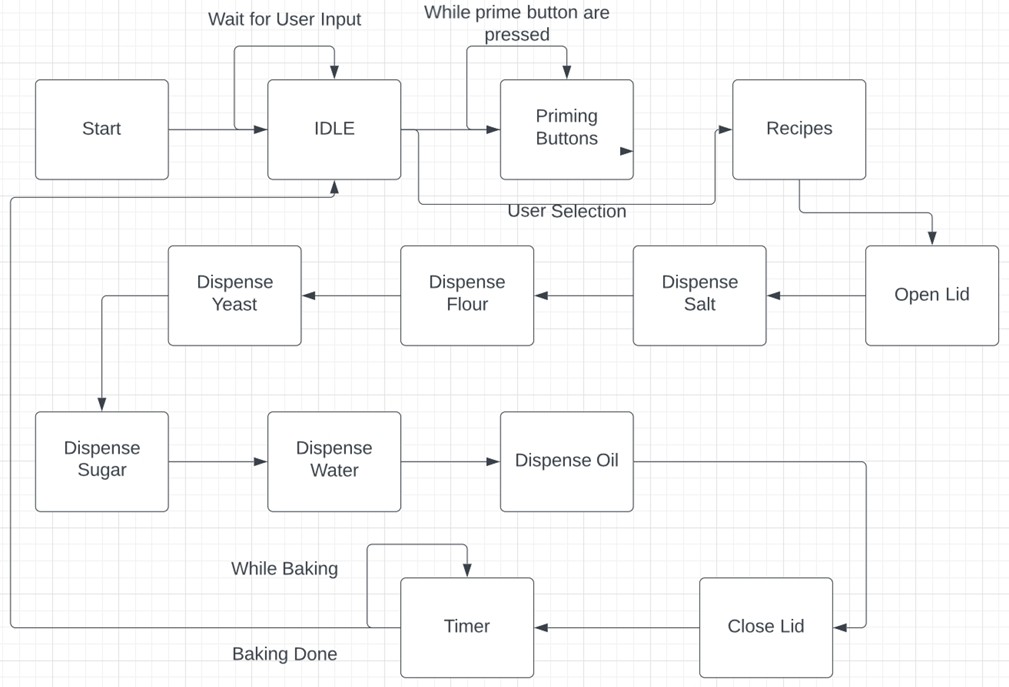

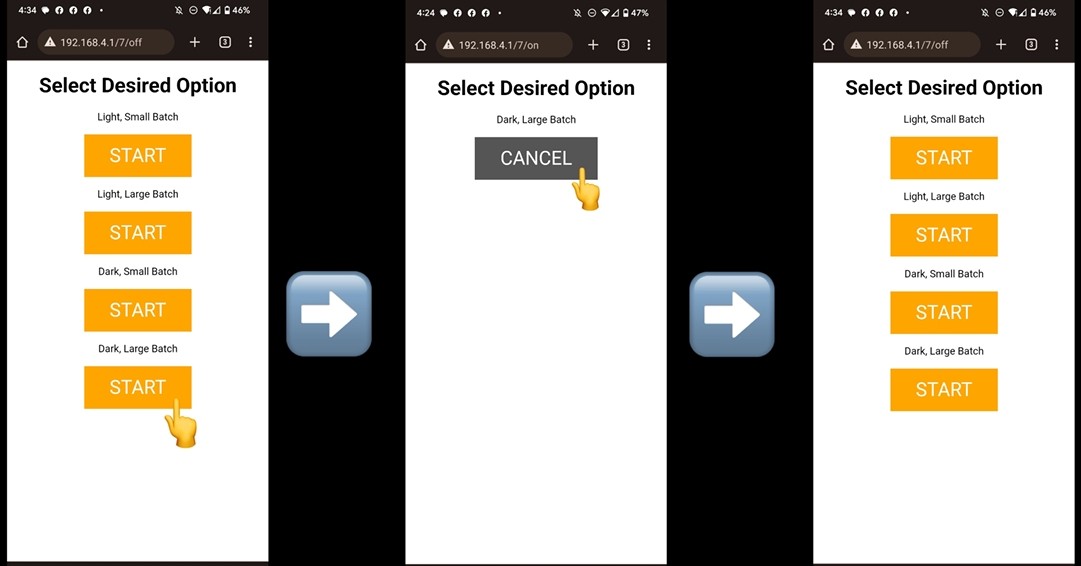

Following the flow of the FSMs, BRAD waits for human input before starting the process. For our project, human input comes in the form of a web app, as shown below. The user has the option to make either light or dark white bread in both small or large batches. In future revisions, more bread recipes can be easily added, as BRAD is designed to be highly modular. Once a button is pressed, the process is started and can be canceled at any time through the web app.

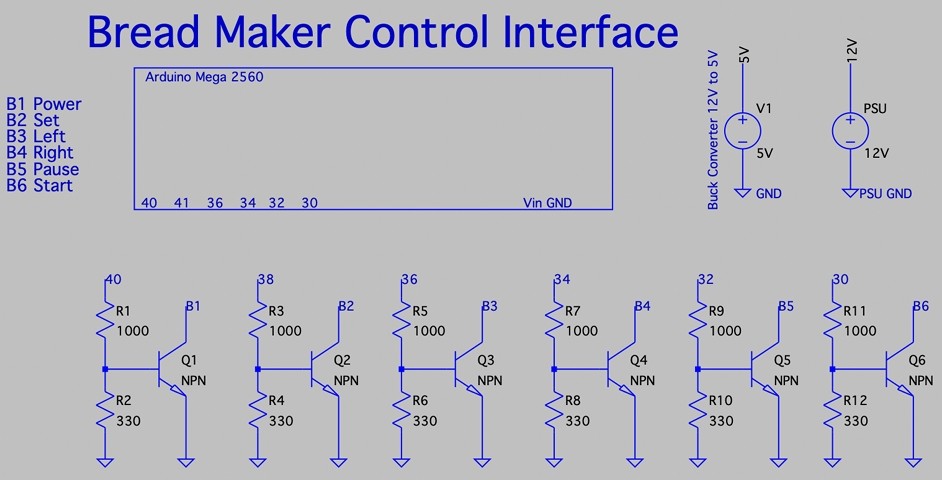

Once the user selects their desired option, the FSMs move to the recipes state where the bread machine interface (shown below) simulates the button presses on the bread machine as a human would.

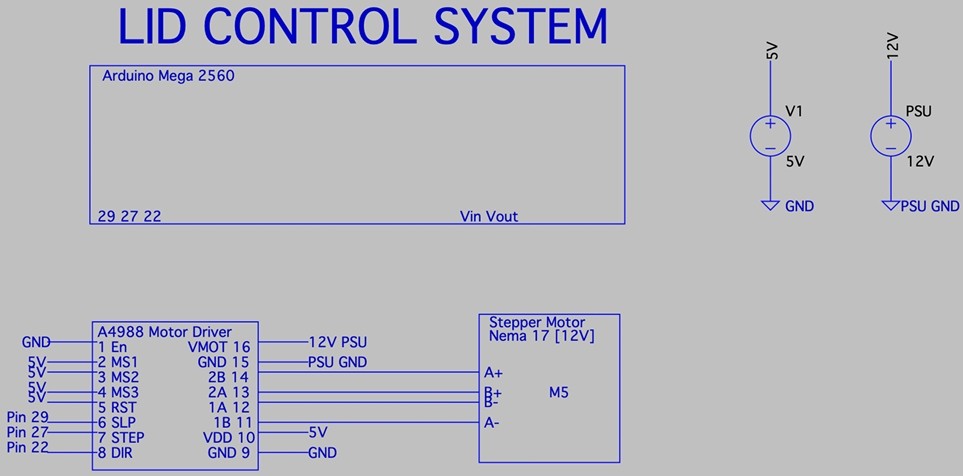

Once the desired buttons are pressed, it is time to load in the ingredients. We start with opening the lid which is controlled by the lid control system. The lid control system as shown below, consists of an A4988 motor driver and Nema 17 stepper motor. The motor spins a 3D printed bit that holds some fishing line that is connected to the lid. As the motor spins, the string winds up and the lid opens. Closing is similar but in the other direction.

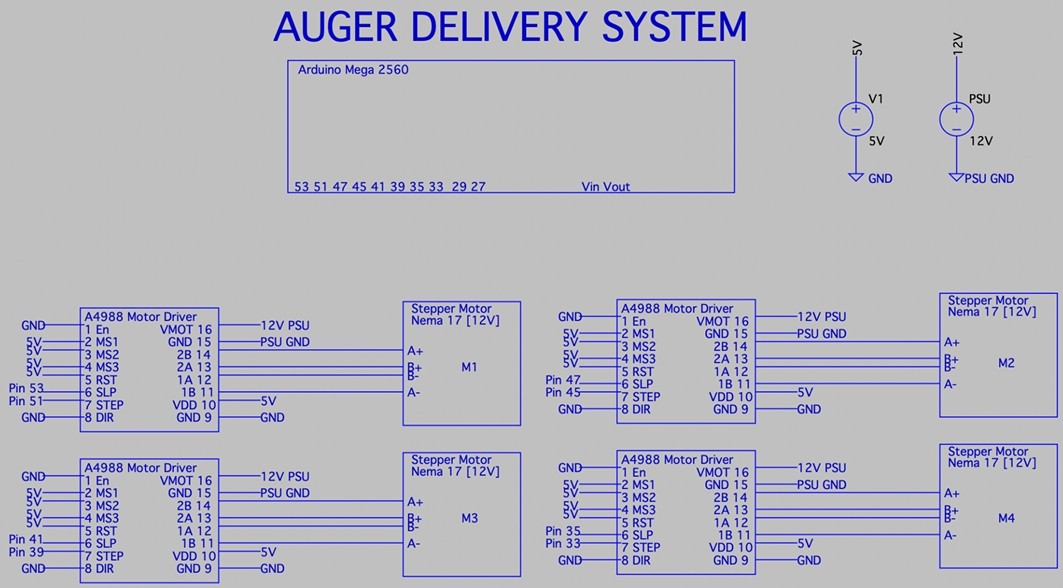

Once the lid is fully open, we are now able to fire up the auger delivery system (shown below) to deliver all the dry ingredients. For the white bread, we pour in salt, flour, yeast and sugar. This is done by using several Nema 17 motors (one for each ingredient) and the auger bits. Spinning the auger moves the ingredient down towards the hole which leads into a funnel where the ingredient falls into the bread maker.

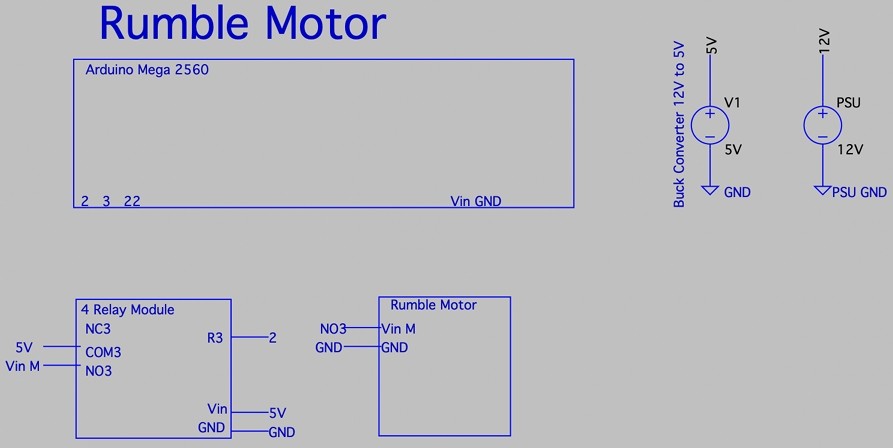

One issue we had was that some of the ingredients would clump up and not move down the funnel. To address this issue, we used a “rumble” motor which is a motor that spins an unbalanced piece of metal. This creates vibration which helps to shake up the clumped up ingredients.

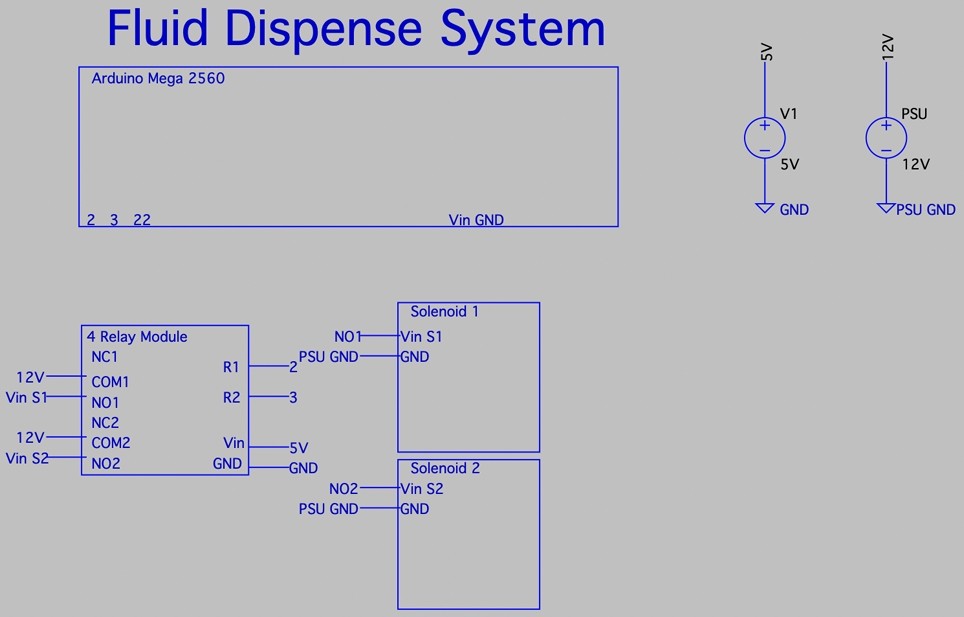

From here, the state machine starts up the fluid dispensing operations. For white bread, we need water and oil. The fluid dispense system (shown below) is composed of a four relay module connected to two solenoids which pump the fluid into the bread maker.

From here, we fire the lid control system back up to close the lid, which then starts the mixing and baking process defined within the bread machine itself. The user can then enjoy their freshly made bread at home.